I am interested in the chuck mounted arbour as I haven't come across one of these, mine are MT arbours with the tail stock stopping it flying out. -- Julian

Hi Julian....sorry it took me a while to reply to this....things got a bit busy towards the end of last week (see gallery posting), but I finally got around to photographing the set-up for you.

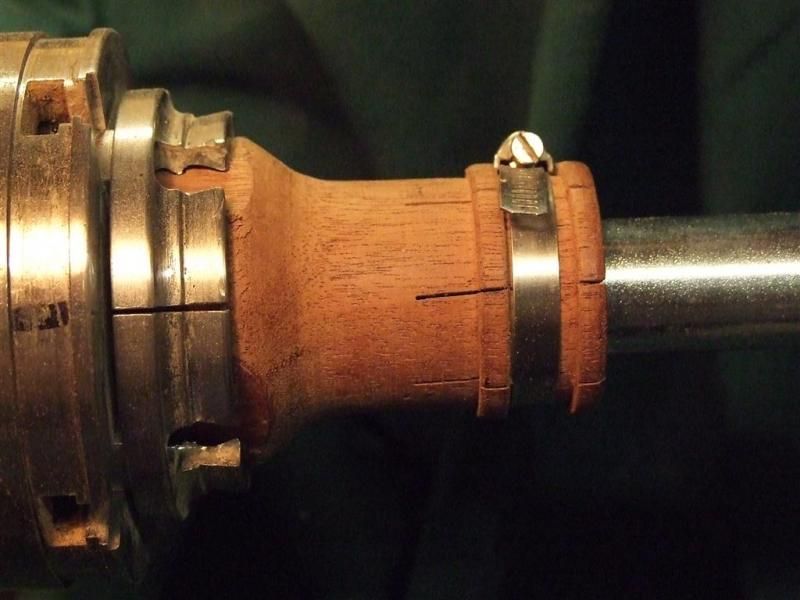

My Chestnut, 3-wheel system came with an arbor that is straight-sided, with one end bored and tapped with female thread to accept the threaded arbors of the Chestnut cotton wheels and mops. I have simply turned a piece of timber with a spigot that fits my 70mm jaws in my Patriot chuck, with a hole in the end to accept the Chestnut metal arbor. These are then held together by a hose clip, which could have a protective covering put over it, but I've never needed that and have been using this system regularly for several months.

The system is good, because it lets me get right inside concave shapes, from bowls, right down to boxes and goblets.

Another advantage of the set-up, is the ease with which it can be used. The metal arbor remains fixed into the wooden piece, which is simply fixed into my chuck. The various wheels and mops can then be changed in a matter of seconds.

Hope this answers your question...Les