This was quite a lump when I started, weighing in at 64lb (25kg) and massively out of balance, so it was turned at a painfully slow speed and despite eventually getting it truly circular, it still wasn't balanced due to the differential in the spalted, punky wood on one side and the hard, dry stuff on the other. I managed to get a little over 16" diameter out of the blank, but it changed shape quite a bit before hollowing of the inside was under way - even though only an hour had gone by.

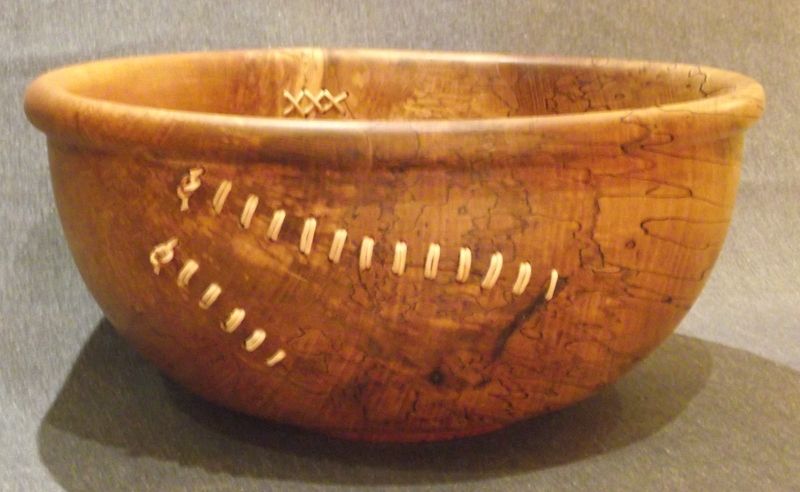

Its finished dimensions are 16" x 8" (40cm x 20cm) with an internal depth of 6.5" (16.5cm), the bottom of the bowl was left very thick because of all the cracks and the bad knot in the walls.....it needed a good strong bottom to keep it in one piece!

It was always my intention to do some stitching on this piece. cracks were evident from the outset and I wanted the bowl to look old and used. I settled for 1/10" (2.5mm) natural leather thong, cross-stitched on the inside, and in straight bars across the splits, on the outside, all set into pre-drilled holes and knotted at the end of each stitch-run, with a reef-knot dabbed with ca adhesive to keep it locked.

The finish is BLO, which took 8 coats before the punky grain filled and finally stopped sucking the oil in. Two further coats eventually gave a gentle sheen.

C&C always welcome....Les